March 2012 - I decided the next item to upgrade was the front and rear sway bars. I decided on the Racing Beat tubular front 1.125" diameter bar and the Mazdaspeed rear 14mm bar. I located the rear bar at 949 Racing's swap meet and I purchased the polyurethane bushings from 949 Racing as well. I also bought what I thought was the Racing Beat front subframe brace from the swap meet but it ended up being their sway bar brace and hardware. I purchased the front sway bar from 949 Racing as well.

Installation was simple on the rear as the stock brackets are used and the new bushings fit right in. The front proved a challenge. I am not sure I did something wrong, but I had trouble starting all 4 bolts for the sway bar brackets. I could get 2 started but when I tried to do the other side the holes didn't line up. I finally got all 4 bolts in and tightened.

Miata Performance Project

Tuesday, April 3, 2012

Thursday, March 29, 2012

Steering - De-Power Rack & Overhaul

February 2012 - While I was installing my poly bushings I noticed that my steering rack bellows were shot and my tie rod boots weren't any better. My car had power steering but it had been disconnected. This is a common practice as the power steering Miatas have "faster" steering and are generally considered more desirable - the number of turns lock-to-lock is less than on a manual rack Miata. Disconnecting the steering pump gives more feel to the steering, but it also makes the steering heavy and more difficult to turn the wheel than on a manual rack Miata. I decided to follow the instructions on the Flyin' Miata website and "de-power" my power rack. What that involved was removing a seal from the rack and plugging up the power steering hard lines. While doing research online I discovered that some people were having their steering input shaft welded as there is some play in the shaft after the rack has been de-powered. The shaft is actually made up of a few separate pieces and a torsion rod - ingenious when part of a power steering system, but it only creates slop after the rack has been de-powered.

The steering rack bellows were way beyond their expiration date.

The tie rod dust boots had seen better days. I will eventually replace both tie rods but for now I just replaced the boots.

This seal drags inside the housing while it would normally have power steering fluid assisting it.

Before and after welding - I traded my friend's dad a case of beer in exchange for his 25+ years of aerospace welding experience. Unlike examples I found online, there are no bluish signs that the metal was excessively heated - nice!

Simple but effective - just trying to keep out dirt and debris so a perfect seal isn't needed.

AWESOME!!!!!!!!!

Tuesday, March 27, 2012

Prothane Urethane Bushings, NB Struts + Ft NB Brace, Ft Ball Joint Boots

January 2012 - I got a good deal on Craigslist for a "new in box" set of Prothane Urethane Bushings. It was a master kit and I decided to install everything except the differential bushings since I plan on a Torsen 1.8L swap in the future. I researched online and found that there are two schools of thought: Burn them out or press them out. I decided on the latter and having completed the task I can't help but wonder why anyone would use fire to extricate them. It is a long process - it took me 14+ hours, but they came out clean and it was fairly simple. I used an idea found on some site that has escaped me now utilizing $10 worth of parts found at Lowes. A threaded rod, fender washers, nuts, and a plumbing pipe to press the bushing into.

I started with the left rear control arms and sway bar endlinks. It is worth noting that I did not remove the axle as some recommended, and I don't know why anyone would go to all that trouble when it is not needed.

Then I tackled the front which was just as straightforward as the rear.

During my brake job, I noticed that my front ball joint boots were shot and my shock assemblies looked as worn as they felt going down the road so it was time for a change. I picked up some new boots at 949 Racing during a swap meet that they held, and I also got a set of 4 NB (1999-2005) shock assemblies that had a coil cut from each spring to lower the car. Eventually I plan on coilovers, but for now this would be a welcome inprovement. The main difference between NA and NB shocks is the upper mount or "tophat" - it allows for increased travel and is a better design. My wife gave me a factory NB front strut tower brace for Christmas that I also took the opportunity to install.

Then I tackled the front which was just as straightforward as the rear.

During my brake job, I noticed that my front ball joint boots were shot and my shock assemblies looked as worn as they felt going down the road so it was time for a change. I picked up some new boots at 949 Racing during a swap meet that they held, and I also got a set of 4 NB (1999-2005) shock assemblies that had a coil cut from each spring to lower the car. Eventually I plan on coilovers, but for now this would be a welcome inprovement. The main difference between NA and NB shocks is the upper mount or "tophat" - it allows for increased travel and is a better design. My wife gave me a factory NB front strut tower brace for Christmas that I also took the opportunity to install.

The shocks had to be disconnected to remove the control arms so they were easy to swap. The upper ball joints looked good but the lowers will need replacement in the near future. The new boots were easy to install using my vise and a large socket.

At this point I needed an alignment, but I was going to tackle the steering rack next so I waited...

Brake Upgrade - 1.8L Bigger Brakes

January 2012 - I decided that a brake upgrade was the next item on my to-do list. Well, the grinding sounds from my rear brakes were the real deciding factor. Rather than replace the pads/rotors with 1991 spec parts, I decided to upgrade my brakes to the later 1994-97 1.8L larger brakes. The only difference is that the brackets are different (and of course the pads and rotors) and I was able to source a set of brackets on Craigslist for a reasonable price and it included the rotors, pads and calipers as well. I was told when I bought the car that it had three stainless steel brake lines and one oem rubber line, so I decided to get the Stage 1 kit from 949 Racing - Carbotech XP8 and XP 10 pads, 4 new rotors, stainless steel lines, and Motul Fluid.

The installation was straightforward except that the hub mounted dust shield/backing plate had to be trimmed to clear the larger rotor. The front had been done before, so I did the back.

I was pleasantly surprised to find out that my car had all 4 Goodrige stainless steel lines and I was able to return my new 949 Racing lines without a hassle.

The Brakes looked great and I took the car out for a test drive to bed my new pads...

and when I returned I was shocked to see this on the left rear rotor:

After some research and some measurements and also a call to Flyin' Miata I came to the conclusion that my caliper was bent. Given the severe damage to the piston face and the measurement of "the fingers" of the caliper that contact the outboard pad, I think that someone tried to force the piston in when doing a pad change and used the "fingers" for leverage. The miata has an adjustment screw in the bck of the caliper and that must be used to retract the piston when changing pads/rotors.

The distance from the finger edge to the piston face was greater than from the piston face to the finger near the bridge over the rotor. Luckily, the used brackets I purchased included calipers so I swapped that one out and the problem seems to be solved.

The installation was straightforward except that the hub mounted dust shield/backing plate had to be trimmed to clear the larger rotor. The front had been done before, so I did the back.

I was pleasantly surprised to find out that my car had all 4 Goodrige stainless steel lines and I was able to return my new 949 Racing lines without a hassle.

The Brakes looked great and I took the car out for a test drive to bed my new pads...

and when I returned I was shocked to see this on the left rear rotor:

After some research and some measurements and also a call to Flyin' Miata I came to the conclusion that my caliper was bent. Given the severe damage to the piston face and the measurement of "the fingers" of the caliper that contact the outboard pad, I think that someone tried to force the piston in when doing a pad change and used the "fingers" for leverage. The miata has an adjustment screw in the bck of the caliper and that must be used to retract the piston when changing pads/rotors.

The distance from the finger edge to the piston face was greater than from the piston face to the finger near the bridge over the rotor. Luckily, the used brackets I purchased included calipers so I swapped that one out and the problem seems to be solved.

Short Shifter

December 2011 - I was perusing the website of Good-win Racing and happened across a closeout Ralco short shifter kit incl knob. The price was right and I ordered. When it arrived I attempted to install, but there was a plastic insert on the fulcrum of the shifter that the stock dowel pin was supposed to slide into and it wouldn't fit. I attempted to remove the insert to gring some away and I broke it in the process. So, I made a trip to a specialty hardware store and after much searching I bought this nylon piece along with some stainless hardware to replace the poor quality bolts included in the kit. Only time will tell, but I feel that my rig job is at least as good as the part that came with the kit. I absolutely love the way it feels and it is one of my favorite upgrades to my car!

Changing Fluids

November 2011 - I decided it was time to do some regular maintenance on my project car that was long overdue. I changed the oil/filter for the first time - I know, regardless of mileage 18 months is WAY too long between changes. I replaced the drain plug with a magnetic one while I was there. I also opted to replace the rear differential fluid with Valvoline synthetic. As for the transmission, I did a bunch of reaearch and the sources I trusted recommended Ford Motorcraft full synthetic manual transmission fluid. At $22 per quart it is rather expensive which is a shame because the pump I bought at the local auto parts store spilled about $30 worth of it all over my garage floor.

Cooling Down - Radiator/Hoses/Thermostat

November 2011 - I have had my Miata for 18 months and have only logged a little over 1,000 miles - not nearly what I had envisioned when I purchased the car. It finally occurs to me that I had better get moving with upgrading my car for the track and to enjoy more on the street as I need some motiviation to get behind the wheel of my Miata instead of my all-expenses-paid company car on the weekends.

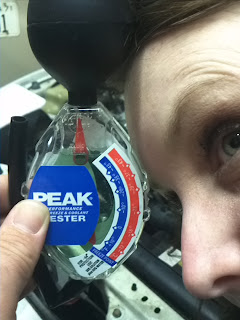

Before I could start the project(s), I was due for a smog check -and- my car started to run hot again. It would overheat mainly at high speeds but not at idle. The radiator looked ok and I was told the water pump had been replaced during a timing belt change just before I purchased the car. I figured it was an old radiator hose that was collapsing at high RPM. I decided to replace the easy stuff: upper and both lower radiator hoses, thermostat, radiator cap, coolant - and I checked the mixture beforehand to make sure that wasn't the issue(it was off, but acceptable).

I felt good and took the car for a spin. Bummer, it still got dangerously hot. When I returned home I remebered my brother Brian gave me an infrared digital thermometer for Christmas last year. It is one of those things you know you want and aside from measuring all of the surfaces in my condo and various parts of my body for teperature differentialsI had never used for a practical reason. I pulled it out of the box and measured the temperature across the radiator - I was getting around 200 degrees at the ends and under 100 in the middle. Aha! A clogged radiator!

I decided that if I was going to replace it, why not upgrade it! I ordered a Koyo 37mm aluminum radiator and cap from 949 Racing and installed it - really nice product.

I found some Royal Purple coolant additive that I had purchased some years ago for a project and never used, so I put that in as well.

My cooling problems were solved and I passed my smog check without a problem :)

Before I could start the project(s), I was due for a smog check -and- my car started to run hot again. It would overheat mainly at high speeds but not at idle. The radiator looked ok and I was told the water pump had been replaced during a timing belt change just before I purchased the car. I figured it was an old radiator hose that was collapsing at high RPM. I decided to replace the easy stuff: upper and both lower radiator hoses, thermostat, radiator cap, coolant - and I checked the mixture beforehand to make sure that wasn't the issue(it was off, but acceptable).

I felt good and took the car for a spin. Bummer, it still got dangerously hot. When I returned home I remebered my brother Brian gave me an infrared digital thermometer for Christmas last year. It is one of those things you know you want and aside from measuring all of the surfaces in my condo and various parts of my body for teperature differentialsI had never used for a practical reason. I pulled it out of the box and measured the temperature across the radiator - I was getting around 200 degrees at the ends and under 100 in the middle. Aha! A clogged radiator!

I decided that if I was going to replace it, why not upgrade it! I ordered a Koyo 37mm aluminum radiator and cap from 949 Racing and installed it - really nice product.

I found some Royal Purple coolant additive that I had purchased some years ago for a project and never used, so I put that in as well.

My cooling problems were solved and I passed my smog check without a problem :)

Subscribe to:

Comments (Atom)